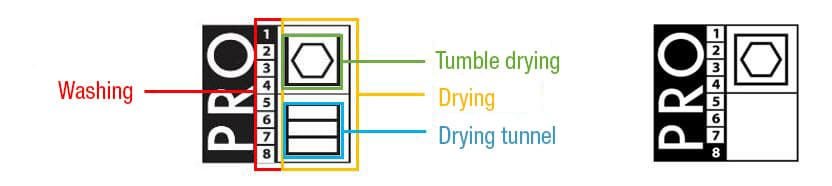

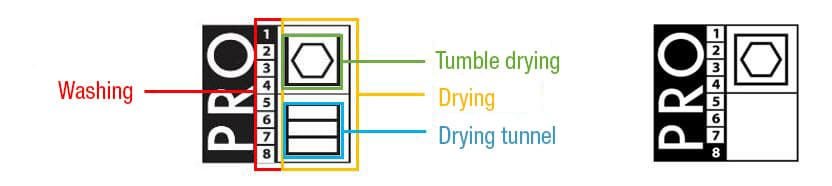

Detail of picto 15797 Industrial washing

The stages of industrial washing

Step 1: Sorting

This step is crucial to differentiate:

- White and colors

- PPE and non-PPI

- Work clothes and flat linen (sheets, tablecloths, …)

In order to send the garments to the right maintenance process.

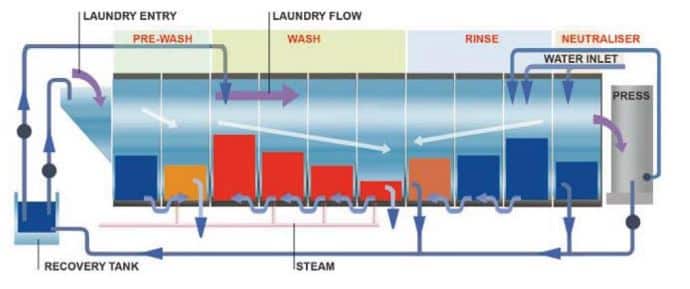

Step 2: Washing

- Washing tunnels: accommodate approximately 50kg of laundry per module

- Washing is done with detergent and chemical products adapted to these materials

- The press at the exit of the washing tunnel: crushes the clothes in order to wring them out (pressure of 6 bars for clothes to 24 for flat linen)

Note:today more and more washes are done at 60°C to respect the fibers and save energy

Step 3: Hanging

Clothes are transported to the staff who place each garment on a hanger

Step 4: Drying

In the drying tunnel:

For 7 minutes, the hangers scroll by

Temperature: between 120 and 160°C (actual temperature on the garment: 143°C)